KEIM Soldalit-ME is a variation of KEIM Soldalit which offers sustainable exterior protection for buildings with the additional environmental benefit that it helps to degrade nitrogen oxide pollutants from the atmosphere.

In addition to improving air quality KEIM Soldalit-ME offers high levels of algae and fungal resistance and actively kills spores and surface contaminants. The paint system contains a catalyst which, when activated by light, degrades surface contaminants. This process is ideal for urban environments where traffic and pollution levels are high, but is increasingly beneficial for any properties or areas which suffer from prolific algae growth and fungal attack as the catalyst will continue to work for the life of the coating.

Keim Soldalit-ME exterior paint is a combination of silica sol and potassium silicate binding agents, creating a high quality, multi purpose exterior paint. Soldalit-ME is suitable for organic, mineral and mixed substrates. It is simple to apply and gives an extremely durable, lightfast and UV resistant coating. The enhanced condensation resistance of this paint makes it extremely durable and resistant to weathering.

Keim Soldalit-ME is a great solution for consolidating walls made up of multiple finishes, forming a chemical bond with mineral substrates and a mechanical bond to existing coatings.

Colours

Keim Soldalit is available in a wide range of colours.

Online colour card - colours 9033-9294 (opens in new tab)

Online colour card - colours 9295-9595 (opens in new tab)

Colours on screen may vary from actual colour and for use as a guide, please order a colour card and preferably a sample pot to ensure colour is correct.

Key features and benefits

Extremely durable

Extremely durable- Highly resistant to weathering

- Breathable, water repellent and highly water vapour permeable

- Economical

- Non flammable

- For use on mineral and previously painted substrates

- Low VOC

- Lightfast and UV stable

- Silicate matt surface appearance

- Environmentally friendly, ISO14001

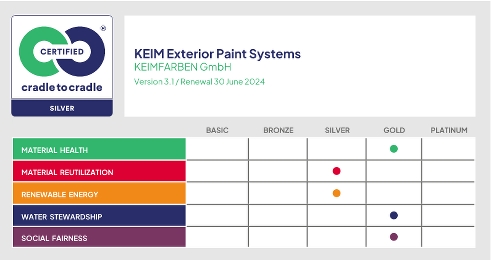

- Cradle to Cradle Certified SILVER

- Resistant to mould and algae

- Easy and safe application

Application

General Preparation considerations for all surfaces

The key to optimum performance with Keim products is preparation prior to decoration.

- Remove flaking and unstable material back to a sound edge.

- Check that any remaining coatings are stable and feather the edges with sand paper.

- Flat down any shiny surfaces with sandpaper to create a good key

- Remove any Mould and Fungal growth and treat the affected area with Keim Algicid.

- Repair cracks with Keim Spachtel filler.

- Ensure air and surface temperatures are between 5-30ºC.

Clean all surfaces with clean cold water to remove dirt, dust and contaminants. Leave surfaces to dry naturally.

Please note: Consumption rates are offered for guideline purposes only. For more accurate measures, site trials should be conducted.

Brickwork

Follow the general preparation guidelines.

Specific considerations for Brickwork

Repair any damaged mortar joints. Newly repaired areas should be left for 15 days before painting.

Application

Apply 2 Coats of Keim Soldalit-ME using a brush, roller or airless sprayer. Leave a minimum of 12 hours between coats.

Typical consumption rates for Brick

Keim Soldalit-ME 0.6 kg per square metre for 2 coats

Lime Render

Follow the general preparation guidelines.

Specific consideration for lime render

New lime render should be left to dry for a minimum of 28 days to allow carbonation to a minimum depth of 2.5mm.

Application

Coat all unpainted surfaces with Keim Soldalit Fixativ, this will help reduce any high surface porosity. Apply the Fixativ with a brush and work well into surfaces. Allow to dry for a minimum of 12 hours.

Apply 2 coats of Keim Soldalit-ME using a brush, roller or airless sprayer, leaving at least 12 hours between coats.

Typical consumption rates for new lime render (smooth finish)

Keim Soldalit Fixativ 0.15 lt per square metre

Keim Soldalit-ME 0.45 kg per square metre for 2 coats

Smooth Painted Surfaces

Follow the general preparation guidelines.

Application

Apply 2 coats of Keim Soldalit-ME using a brush, roller or airless sprayer, leaving at least 12 hours between coats.

Typical consumption rates for a smooth surface

Keim Soldalit-ME 0.45 kg per square metre for 2 coats

Roughcast / Pebble Dash

Follow the general preparation guidelines.

Specific consideration for Roughcast / Pebbledash

Any newly rendered/repaired areas must be allowed to dry out for a minimum period of 15 days prior to paint application

Application

Prime any new/bare lime render using the Soldalit Fixativ, applied neat by brush and worked well into the surface. Avoid contact with previously painted surfaces and allow a minimum period of 12 hours before proceeding.

Apply 2 coats of Keim Soldalit-ME using a brush, roller or airless sprayer leaving at least 12 hours between coats:

Dilute the first coat with approx. 20% (by Weight) of Keim Soldalit Fixativ

Dilute the second coat with approx. 5% (by weight) of Keim Soldalit Fixativ

Typical consumption rates for a Roughcast / Pebbledash surface

Primer coat (New / Bare Lime Render)

- Keim Soldalit Fixativ 0.15 lt per square metre

First Coat – 20% dilution

- Keim Soldalit-ME 0.4 kg per square metre

- Keim Soldalit Fixativ 0.08 lt per square metre

Second Coat – 5% dilution

- Keim Soldalit-ME 0.4 kg per square metre

- Keim Soldalit Fixativ 0.02 lt per square metre

Downloads:

Keim Soldalit ME Brochure

Keim Soldalit ME Technical Data Sheet

Keim Soldalit ME Safety Data Sheet

Cradle to Cradle Certification

Cradle to Cradle Certified® is the world’s most advanced, science-based standard for designing and making products today that enable a healthy, equitable, and sustainable tomorrow. Independent third parties examine and assess the substances contained in all products.

Cradle to Cradle Certified® sees materials as substances that are made available to new processes after use. All substances contained in the products must therefore be assessed scientifically for circularity.

All interior paints by KEIM have been awarded the Cradle to Cradle Certified® certificate in SILVER. In the areas of material health, water management and social fairness, the products achieved gold certification (the overall certification result is based on the lowest rated criterion).